From onboarding to production, a controlled manufacturing process is implemented to ensure client’s requirements and regulatory standards are met.

- Onboarding – learning our client’s process, specification, requirements, and expectations.

- Planning – an account administrator will review the information provided and map a quality plan that will best fit the project.

- R&D/Rapid Prototyping – our experienced machinists will fabricate the Frist Article. Clients will have an opportunity to review and validate upon request.

- NPI – an experienced manufacturing specialist will work with clients to plan and implement any ECO and finalize the quality planning.

- Production – Quality metric is established, process specific to client’s requirements are implemented, and production scaling in in progress.

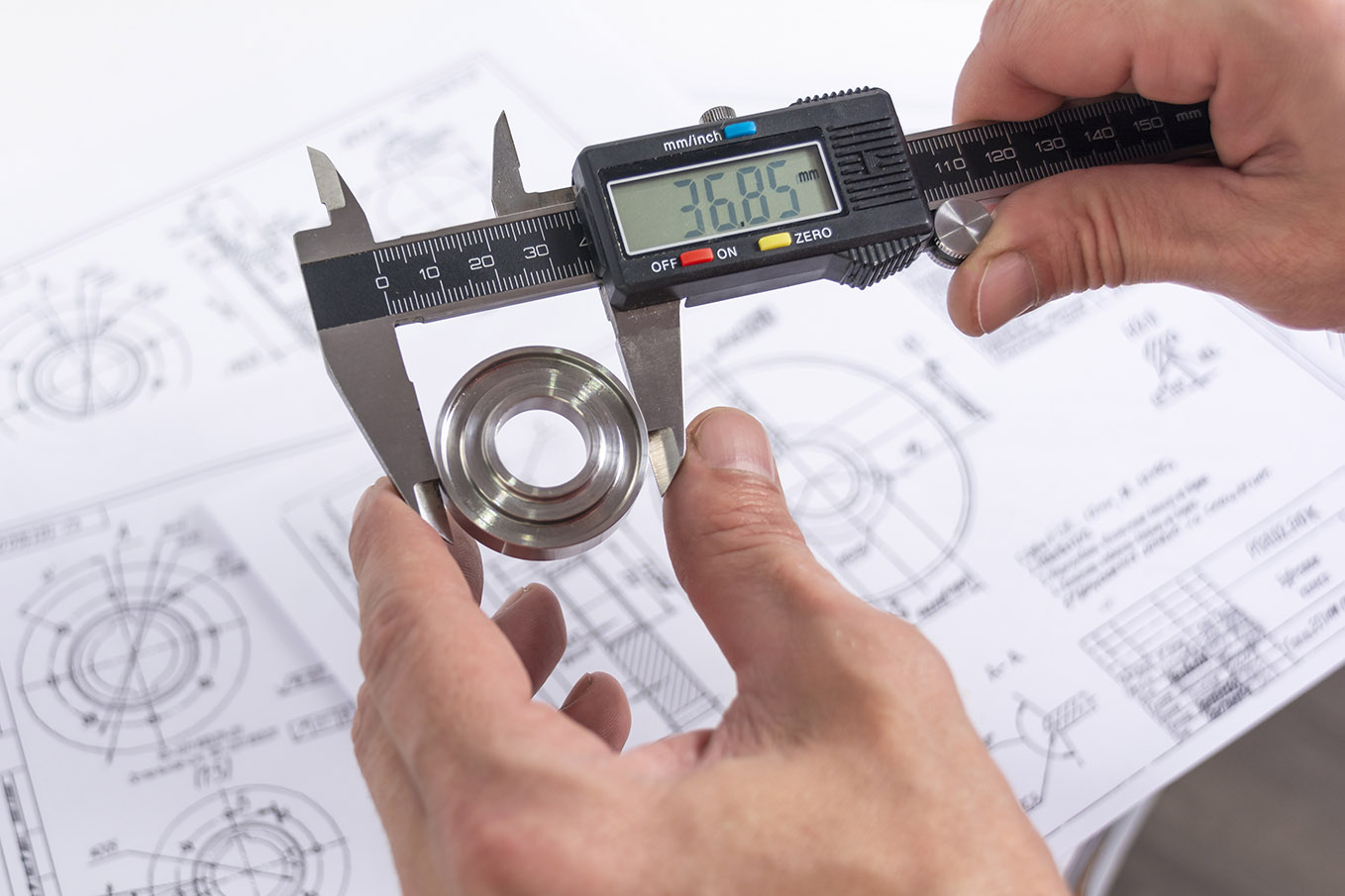

What happens during the in-process fabrication?

Process Control

Team members are trained in process control with an emphasis on processes related to their individual duties.

01

Quality Control

First Article, work in progress, and final inspection samplings are quality assessments used to ensure quality is consistently achieved.

02

Continuous Improvement

This practice encourages all team member to actively use their knowledge to make improvements.

408-573-7252

408-573-7252